Measurement FundamentalsCalibration

“Calibration,” when used with industrial products, refers to a Series of operations performed to ascertain differences between actual equipment values and reference values. If values obtained by a measurement system are not as expected, users should contact the system manufacturer's support department and request calibration. If measurement system adjustment is deemed necessary following calibration, adjustment should be performed by the manufacturer in order to return the system to optimal conditions. Proper calibration allows manufacturers to ensure stable quality throughout manufacturing and inspection processes. It should be generally accepted that measured values might change over time as measurement systems are continuously used. As such, regular calibration and adjustment should be considered essential.

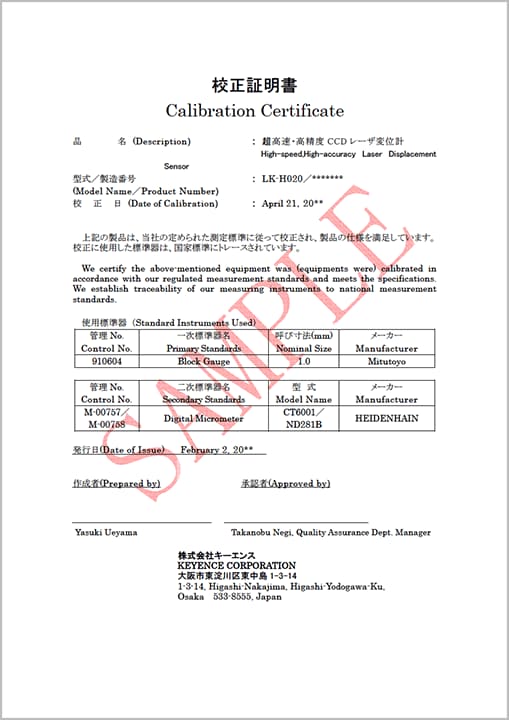

Calibration Certificate

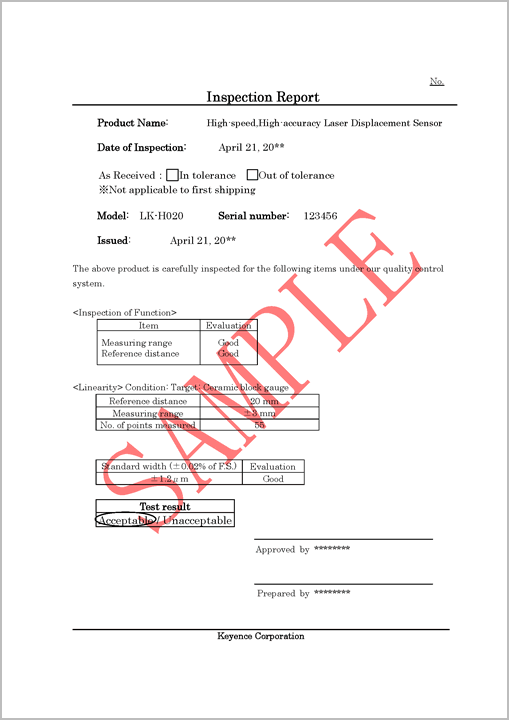

Calibration certificates are documents that show the calibration results for a measurement system. When requesting calibration in addition to regular measurement system maintenance, this document will be included when the device is returned. Calibration certificates also serve as the evaluation standard for explicitly proving that calibration was performed by the manufacturer or service provider responsible. Similar documents include testing certificates and inspection reports.

Although usage may vary from one manufacturer to the next, the generally accepted terms are defined as follows.

| Calibration | The Series of operations performed to determine the relationship between the values obtained using an instrument or measurement system, or the values obtained by a material measure or standard reference material values, and the values implemented by a standard. Note: Calibration does not include error correction through instrument adjustment. (JIS Z 8103) |

|---|---|

| Testing | The determination of one or more characteristics of a conformity assessment target. Note: Testing is typically performed for a material, product, or process. (JIS Q 17000) |

| Inspection | The investigation of a product design, product, process, or installation, as well as the confirmation of conformance to relevant performance requirements, or the confirmation of conformance to general requirements based on professional judgement. Note: Process-related inspections may include inspections of workers, facilities, technical approaches, and methods. (JIS Q 17000) |

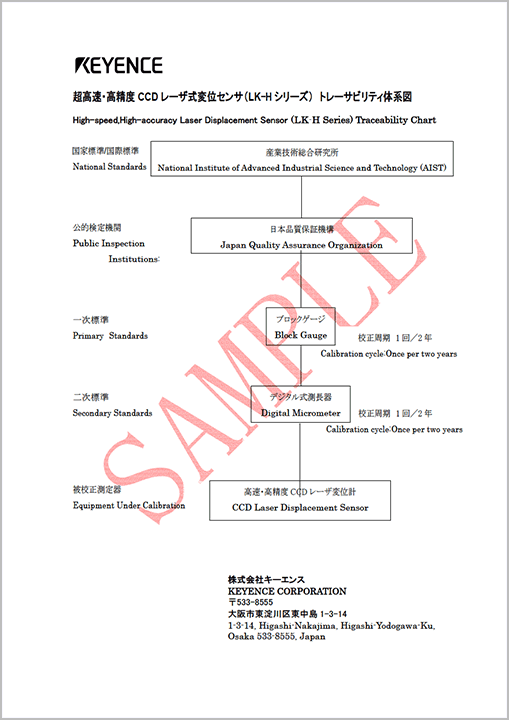

Traceability System Diagram

Traceability can be defined as “the property of the result of a measurement or the value of a standard whereby it can be related to stated references, usually national or international standards, through an unbroken chain of comparisons all having stated uncertainties.” Traceability system diagrams (charts) are documents that describe the calibration process for any equipment used in calibrating a device. Such diagrams can be used to trace which references were used by moving toward a higher position. (Moving up in positions will ultimately lead to the national standards.) Being able to follow the calibration chain backward without interruption is referred to as a “traceable” condition.