Least Material Condition (LMC)

The least material condition is used to manage the size and position of holes, as well as the thickness of the material.

For example, if a part’s hole has imprecise size or position under the least material condition (the hole has maximum size), the part will have insufficient strength and may break. The least material requirement is useful for designing parts with such strict space requirements.

Using Least Material Condition

The most undesirable condition in terms of designing thickness is when the hole diameter is large (least material size) and the hole is positioned close to the edge. In contrast, when the hole diameter is small (maximum material condition), strength can be maintained even when the hole is close to the edge.

- a

- The side of the hole is so close to the edge that the hole might break.

What Is ?

To apply the least material condition to a dimension, you write after the size tolerance in the feature control frame. In some cases, a datum symbol may be followed. “L” stands for “least material condition” (LMC). This symbol indicates the application of least material requirement.

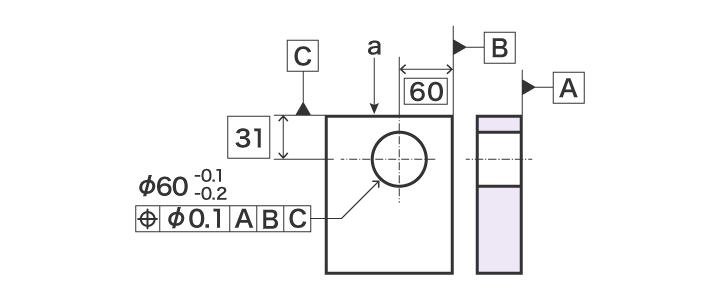

Sample Indication of Least Material Condition

The following drawing is an example of indicating the least material condition for the edge and hole when the minimum thickness is indicated using true position.

When is applied to the size tolerance zone, the true position specification Φ0.5 is only applied when dia. 24 hole is in its least material condition Φ24.1. The geometric tolerance increases as the hole gets smaller.