- Home

- Solutions

- Traceability Solutions for the Automotive

- Laser Marking

Traceability Solutions for the Automotive (Laser Marking)

Advantages of KEYENCE Laser Markers

Auto-focus function

Our built in camera makes it possible to perform automatic focusing without the use of any external devices. This makes it possible to mark parts that are not at the same focal distance, and eliminates the need for external tooling. Additional production costs can be kept to a minimum while increasing efficiency and throughput.

* The built-in camera is used to monitor the focal distance using the laser pointer.

Automatic focusing is performed by calculating the focal distance from the pointer position. This measurement may not be possible in some cases due to the material, shape, and surface of the workpiece.

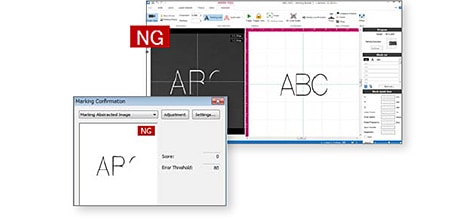

Marking verification

Images are captured by the built-in camera before and after marking in order to verify marking. The contrast differences between the two images are compared and thresholds can be set in order to automate marking confirmation. This, in turn, prevents mis-marking.

Leaser Markers Lineup

-

- 3-Axis Hybrid Laser Marker

- MD-X Series

- The MD-X Series is equipped with our newly developed laser oscillation technology that combines the characteristics of YVO4 and fibre laser marking machines. It delivers high quality and high speed to match a wide range of production needs for every industry.

-

- 3-Axis Fibre Laser Marker

- MD-F Series

- A combination of best-in-class 50 W output and 3-Axis control. Once again, KEYENCE leads the way in cutting edge laser marking technology.

-

- 3-Axis CO2 Laser Marker

- ML-Z Series

- The ML-Z creates precise marking and reduced deformation on targets with varying surface shape and height.

Downloads

Traceability Solutions (PDF: 2.86MB)

Laser Marking Applications For The Automotive Industry (PDF: 4.64MB)

Laser Marking Applications for Electronics Industry (PDF: 2.58MB)

Marking Product Lineup (PDF: 6.76MB)

- PLEASE

CONTACT US